This guide provides comprehensive instructions for building your own laser cutter, covering everything from initial planning and component selection to assembly, calibration, and essential safety protocols. Whether you aim to cut non-metals with a CO2 laser or tackle metals with a fiber laser, this article will equip you with the necessary knowledge.

DIY Laser Cutter Feasibility: Why Build and What to Know

Embarking on a DIY laser cutter project presents exciting opportunities. The primary motivations include significant cost savings compared to commercial units, a rewarding (though steep) learning curve in mechanics and electronics, and the ability to customize the machine’s size, power, and features to your specific needs.

A successful build requires a foundational skill set. Basic knowledge of electronics is essential for wiring, while mechanical aptitude is needed for frame assembly and alignment. Familiarity with CAD (Computer-Aided Design) software is crucial for creating designs, and strong problem-solving skills are invaluable. Proper planning also involves considering your investments. The budget can vary widely based on laser type and component quality. Be prepared for a significant time commitment for research, assembly, and calibration. Finally, a dedicated workspace that can accommodate the machine and its ventilation system is necessary.

Defining your project goal is the first critical step. The materials you intend to cut will dictate the appropriate laser technology. CO2 lasers excel with non-metals like wood and acrylic, while fiber lasers are superior for cutting metals.

Laser Technology Core: CO2 vs. Fiber Lasers Explained

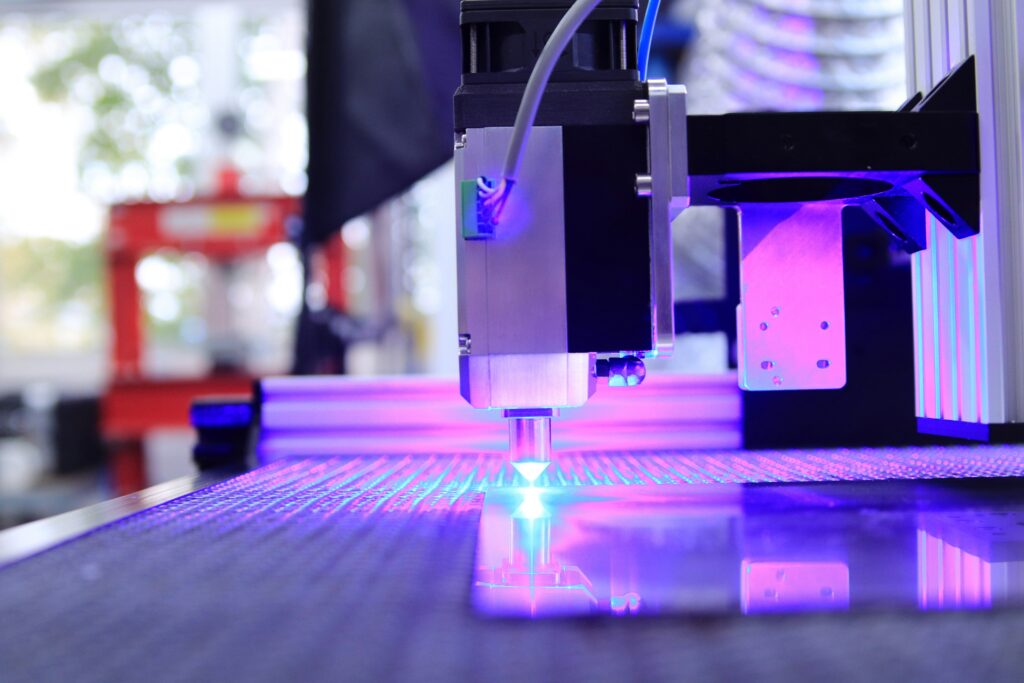

Choosing the right laser technology is fundamental to your DIY laser cutter’s success. CO2 lasers generate light by exciting CO2 gas molecules, operating at a 10.6-micrometer wavelength that is highly effective for non-metallic materials like wood, acrylic, leather, and paper. While some high-power CO2 lasers can cut thin mild steel with an oxygen-assist gas, their efficiency on metals is low.

Fiber lasers, in contrast, use an optical fiber doped with rare-earth elements, operating at a shorter wavelength around 1.06 micrometers. Metal surfaces absorb this wavelength far more effectively, resulting in higher efficiency, faster cutting speeds, and superior precision when processing steel, aluminum, and brass. Fiber lasers can also handle reflective metals, which pose a significant risk to CO2 systems.

When comparing the two, CO2 lasers generally have a lower initial cost for non-metal applications but require more frequent maintenance, such as mirror alignment and tube replacement. Fiber lasers have a higher upfront cost but offer better long-term value for metal-focused work due to lower maintenance, longer source lifespan, and higher electrical efficiency. For mixed material applications, a fiber laser is the better choice if regular metal cutting is a primary requirement.

Key Laser Components: Machine Heart and Skeleton

A DIY laser cutter comprises several critical components that form the machine’s core.

- Laser Source and Power Supply: This is the heart of the machine. For a CO2 laser, this is a glass tube containing a gas mixture, excited by a high-voltage power supply. For a fiber laser, it’s a compact, solid-state module.

- Optics and Laser Cutting Head: The optical system guides and focuses the beam. A CO2 system uses a series of mirrors to direct the beam to a laser cutting head containing a focus lens. A fiber laser delivers the beam via an armored fiber optic cable directly to a more complex laser cutting head. This laser cutting head contains collimating and focusing lenses, protective windows (consumables), and a nozzle for assist gas. A capacitive height sensor is essential for fiber lasers to maintain a precise distance from the metal surface.

- Motion System: This controls the laser head’s movement. Stepper motors with belts and pulleys are a cost-effective choice for many CO2 lasers. For high-speed metal cutting with fiber lasers, servo motors and ball screws are preferred for their superior speed, accuracy, and rigidity.

- Laser Control System: The controller board is the machine’s brain. Low-cost, GRBL-based controllers are popular for DIY CO2 lasers, often paired with software like LightBurn. Dedicated DSP controllers (e.g., Ruida for CO2; CypCut for Fiber) offer more advanced, standalone functionality and are standard on higher-end machines.

- Frame and Workbed: The frame, often made from aluminum extrusions or welded steel, must be rigid and stable to ensure accuracy. The workbed supports the material; a honeycomb bed is common for CO2 lasers, while a knife-blade (slat) bed is essential for fiber lasers to reduce back-reflection.

Supporting Systems: Ensuring Stability and Efficiency

Several supporting systems are vital for stable and safe operation.

- Cooling System: Lasers generate significant heat. A dedicated water chiller is highly recommended for CO2 lasers and is absolutely essential for fiber lasers to maintain precise operating temperatures.

- Exhaust and Ventilation: Laser cutting produces hazardous smoke and fumes. A powerful fan or blower connected to ducting is crucial to vent these particles outdoors or through a filtration system.

- Assist Gas System: Blown coaxially with the laser beam, assist gas expels molten material. For fiber lasers cutting metal, this is essential. Oxygen is used for cutting mild steel (creating an exothermic reaction), while nitrogen is used for stainless steel and aluminum to prevent oxidation and achieve a clean edge.

DIY Laser Cutter Assembly and Software

The assembly process begins with a detailed plan or blueprint. First, assemble the frame, ensuring it is square, level, and rigid. Next, install the motion system components—linear rails, motors, and drives—ensuring careful alignment. Integrate the laser source and optical path, which for a CO2 laser involves mounting the tube and mirrors, while for a fiber laser it means carefully routing the fiber optic cable. Finally, wire the control system, connecting the controller, drivers, and power supplies meticulously according to a wiring diagram.

Software is the interface to your machine. This includes CAD software (e.g., Inkscape, Fusion 360) to create designs, and CAM/control software (e.g., LightBurn, CypCut) to generate toolpaths and send instructions (G-code) to the laser. The firmware (like GRBL) on the controller board interprets these commands.

Precision Calibration and Maintenance

After assembly, calibration is critical for accuracy. This involves squaring the gantry, tensioning belts correctly, and calibrating the steps/mm for each axis. For CO2 lasers, meticulous beam path alignment is required to ensure the beam is centered through the optics. For both types, the laser must be precisely focused on the material. Finally, you must optimize cutting parameters—power, speed, and assist gas pressure—for each material by running systematic tests.

Routine maintenance preserves performance. Regularly clean all optics (mirrors, lenses, protective windows) to prevent power loss and damage. Lubricate mechanical components like rails and ball screws. Check the cooling system and clean the exhaust system.

Laser Safety Protocols: Protecting Yourself and Your Workspace

Adhering to strict safety protocols is non-negotiable.

- Eye Protection: Always wear safety goggles rated for the specific wavelength of your laser. CO2 (10,600 nm) and fiber (1,060 nm) goggles are not interchangeable.

- Equipment Safety: A full machine enclosure is highly recommended to contain stray radiation and fumes. Install safety interlocks on all access doors to shut off the laser if opened, and ensure a visible Emergency Stop (E-Stop) button is present.

- Fire and Fume Safety: Maintain robust ventilation and keep a CO2 fire extinguisher readily accessible. Never leave an operating laser unattended.

- Electrical Safety: Ensure all wiring is properly insulated and grounded. Use extreme caution around high-voltage power supplies.

- Fiber Laser Special Warning: Fiber lasers are especially dangerous because their beam is invisible and can cause instant, severe eye damage. Reflections from metal are a major hazard. A fully interlocked, light-tight enclosure is essential for any open-beam fiber laser system.