Storing and handling the bulk of lead ingots is an essential task in sectors like battery manufacturing, construction, or even metalworking, in which lead’s long-lasting properties are highly appreciated. But, the toxicity of lead requires strict safety guidelines to safeguard employees and the surrounding environment. The proper handling of lead bulk ensures compliance with the regulations and minimizes health hazards.

The implementation of robust safety standards in the handling of lead bulk is essential for firms that wish to preserve productivity and well-being of workers. In everything from storage conditions to handling procedures, this guide provides the most important practices for safely handling massive quantities of lead that ensure safety as well as compliance with regulations for industrial processes.

Safe Storage Practices

Choosing Proper Storage Locations

Ingots of lead should be stored in air-conditioned, dry areas that are well ventilated and far from sources of water in order to stop corrosion. Storage areas that are designated for lead reduces the chance of contamination as well as any unauthorized access. This ensures safety.

Using Protective Containers

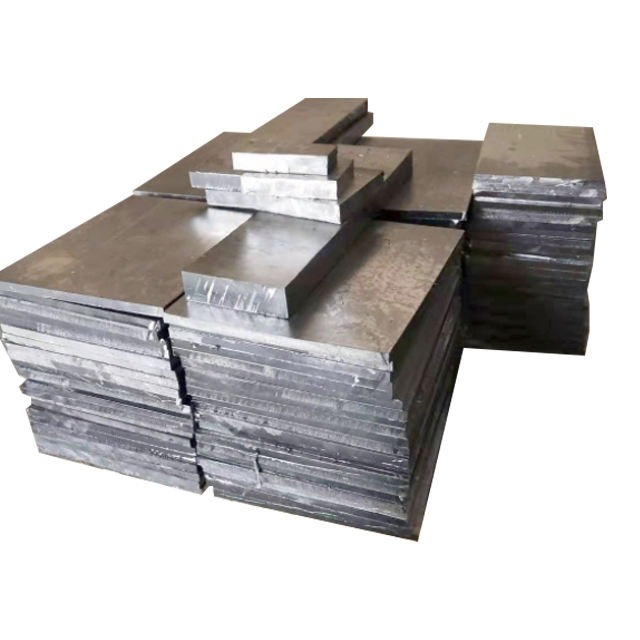

Put lead bulk in sealed, marked containers or on pallets so that dust is not exposed. Containers should be durable as well as corrosion-resistant and built to withstand the load of massive ingot quantities.

Controlling Environmental Conditions

Keep storage spaces at steady temperature and with low humidity in order to stop the formation of oxidation. Inspections on a regular basis for leaks and spills can help maintain the lead’s integrity and safeguard workers in the vicinity.

Implementing Access Restrictions

Access to storage areas should be restricted to authorized personnel only. Signs and barriers that are clear stop accidental exposure and ensure that only those who are authorized can handle or touch lead ingots.

Handling Procedures for Safety

Wearing Protective Gear

The workers must wear Personal Protective Equipment (PPE) which includes respirators, gloves and protective clothing when working with lead. It reduces contact with skin as well as the inhalation of potentially hazardous smoke or dust.

Using Proper Lifting Equipment

Lead ingots weigh a lot and therefore you must use forklifts as well as cranes when moving huge quantities. Be sure the equipment is suitable for the load of lead bulk to prevent accidents or spills while transporting.

Avoiding Dust Generation

Take care when handling the ingots so that you minimize dust that could release lead particles in the air. Make use of tools such as vacuums equipped with HEPA filters to collect any airborne contaminants.

Training Workers Thoroughly

Give comprehensive instruction in lead safety, safe handling, and emergency procedure. Continuous refresher training ensures that employees remain informed of the latest best practices in practice and regulations.

Regulatory and Environmental Compliance

Adhering to Safety Standards

Be aware of international and local regulations like those that govern the limits of exposure to lead. The compliance of standards is important and helps avoid penalties, especially those who handle huge quantities of lead.

Monitoring Exposure Levels

Test regularly both surface and air samples inside places for storage and handling in order to check lead levels. Utilize certified laboratories to ensure that you are in compliance with workplace health and safety standards, as well as protect employees.

Managing Waste Properly

Remove any lead-contaminated material including PPE and packaging by utilizing certified hazardous disposal facilities. The proper waste management prevents environmental contamination and assures compliance to regulations.

Maintaining Detailed Records

Keep track of all handling, storage and disposal processes. Recordings of training, inspections and checks for compliance provide evidence of traceability and prove your commitment to safety when audits are conducted.

Conclusion

The safe storage and handling lead bulk ingots require meticulous plan and adhering to the strictest procedures. When using proper storage conditions, using safe handling techniques, and making sure that the company is in compliance with regulations, they can safeguard their employees as well as the environment, while ensuring operating efficiency. These regulations not only limit dangers but also promote an environment of safety, assuring responsible handling of lead ingots used in industrial environments.